The Essential Guide To Industrial Chemical Pumps: Applications And Maintenance Tips

Are you looking to optimize your industrial processes with the right chemical pumps? Look no further than our comprehensive guide on industrial chemical pumps, featuring essential applications and maintenance tips to keep your operations running smoothly. Whether you're a seasoned engineer or new to the industry, this article is a must-read for anyone seeking efficiency and reliability in their chemical pumping systems. Dive in and discover how you can elevate your operations with the right knowledge and tools.

- Understanding the Different Applications of Industrial Chemical Pumps

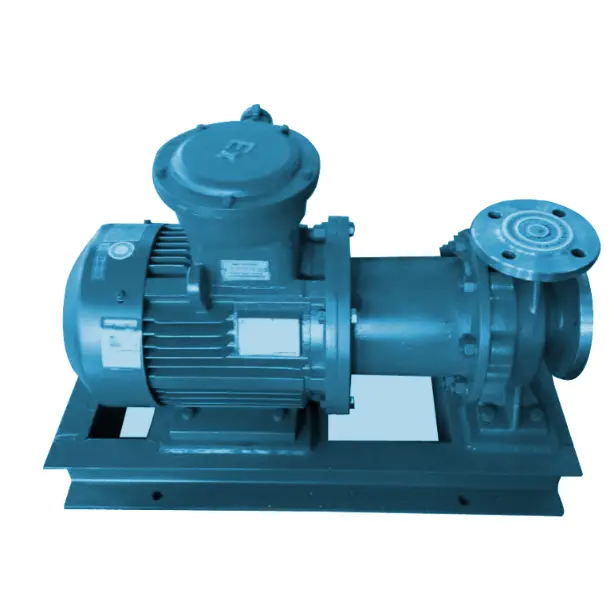

Industrial chemical pumps are essential tools in a wide range of industries, from manufacturing and mining to agriculture and wastewater treatment. These pumps are specifically designed to handle a variety of chemicals, solvents, and corrosive materials, making them indispensable in processes where the safe and efficient transfer of these substances is crucial.

When it comes to understanding the different applications of industrial chemical pumps, it is important to first consider the various types of pumps available on the market. Centrifugal pumps, which use rotational energy to transfer fluids, are commonly used in industrial settings due to their high flow rates and efficient operation. Diaphragm pumps, on the other hand, are ideal for handling abrasive and viscous fluids, making them a popular choice for chemical processing applications.

One of the key applications of industrial chemical pumps is in the transfer of acids, bases, and other corrosive materials. In industries such as chemical manufacturing and pharmaceutical production, where the handling of caustic substances is routine, it is essential to have reliable pumps that can safely and efficiently move these materials from one location to another. Industrial chemical pumps are specially designed to withstand the harsh conditions associated with these materials, with materials such as stainless steel and Hastelloy commonly used to prevent corrosion and ensure long-term durability.

Another common application of industrial chemical pumps is in the handling of solvents and volatile organic compounds (VOCs). These substances are often used in processes such as painting, printing, and cleaning, where their efficient transfer is crucial to maintaining productivity and meeting safety regulations. Industrial chemical pumps with leak-proof seals and robust construction are essential for preventing the escape of these harmful substances into the environment, protecting both workers and the surrounding community from potential health hazards.

In addition to their applications in handling corrosive and volatile materials, industrial chemical pumps are also used in a variety of other processes, such as wastewater treatment, food and beverage production, and mining operations. In each of these industries, the safe and efficient transfer of chemicals and other materials is essential for maintaining operations and meeting regulatory requirements. Industrial chemical pumps play a critical role in ensuring that these processes run smoothly, with minimal downtime and maximum productivity.

In conclusion, industrial chemical pumps are versatile tools that are used in a wide range of applications across various industries. Whether it is transferring corrosive acids, handling volatile solvents, or processing wastewater, these pumps are essential for ensuring the safe and efficient transfer of chemicals and other materials. By understanding the different applications of industrial chemical pumps and following recommended maintenance tips, industries can maximize the performance and longevity of these critical pieces of equipment.

- Essential Maintenance Tips for Industrial Chemical Pumps

If you work in an industrial setting that involves handling chemicals, then you likely understand the crucial role that industrial chemical pumps play in the operation of your facility. These pumps are essential for transferring various types of chemicals from one location to another, ensuring the smooth and efficient running of your processes. In this comprehensive guide, we will explore the applications of industrial chemical pumps and provide you with essential maintenance tips to help you ensure the optimal performance and longevity of these critical pieces of equipment.

Industrial chemical pumps are specifically designed to handle the unique challenges associated with pumping corrosive and abrasive chemicals. These pumps are constructed from materials such as stainless steel, Hastelloy, or PVC, which are resistant to the harsh effects of chemicals. They are also equipped with features such as seals and gaskets that prevent leaks and ensure the safe transfer of chemicals without contamination. Industrial chemical pumps are used in a wide range of applications, including chemical processing, wastewater treatment, pharmaceutical manufacturing, and more.

When it comes to maintaining industrial chemical pumps, there are several key tips that can help you maximize their efficiency and lifespan. One of the most important maintenance tasks is regularly inspecting the pump for signs of wear and tear. Check for leaks, cracks, or corrosion on the pump housing, impeller, and seals. Replace any damaged components immediately to prevent further damage to the pump and avoid costly downtime.

Another essential maintenance tip is to regularly lubricate the pump bearings and shaft to reduce friction and prevent overheating. Proper lubrication will also help to extend the lifespan of the pump and ensure smooth operation. Additionally, it is important to regularly clean the pump and remove any debris or buildup that may affect its performance. Use a mild detergent and water to clean the pump thoroughly, making sure to remove any residue or contaminants that could potentially damage the pump.

In addition to regular maintenance tasks, it is also crucial to monitor the performance of the pump and address any issues promptly. Keep an eye on the pump's flow rate, pressure, and temperature, and be on the lookout for any abnormal noises or vibrations. If you notice any changes in the pump's performance, investigate the issue immediately and take the necessary steps to rectify it.

By following these essential maintenance tips for industrial chemical pumps, you can ensure that your equipment operates efficiently and reliably, minimizing the risk of costly downtime and potential safety hazards. Remember that proper maintenance is key to prolonging the lifespan of your industrial chemical pumps and optimizing their performance. Incorporate these maintenance tips into your routine maintenance schedule to keep your pumps running smoothly and effectively for years to come.

- Choosing the Right Pump for Your Industrial Chemical Application

In the vast world of industrial manufacturing and processing, the use of chemicals is essential for various operations. From the production of pharmaceuticals and food items to water treatment and oil refining, industrial chemicals play a crucial role in ensuring the smooth functioning of various industries. However, one of the key components that often goes unnoticed is the industrial chemical pump, which is responsible for the safe and efficient transfer of chemicals within the industrial setting.

Choosing the right pump for your industrial chemical application is crucial to the success of your operations. With a wide range of pumps available in the market, it can be overwhelming to select the best one for your specific needs. Factors such as the type of chemical being handled, the flow rate required, the pressure needed, and the temperature of the chemical must all be taken into consideration when selecting a pump.

When it comes to industrial chemical pumps, there are different types to choose from, including centrifugal pumps, diaphragm pumps, peristaltic pumps, and gear pumps. Each pump has its own set of advantages and disadvantages, depending on the nature of the chemical being pumped and the requirements of the application. For example, centrifugal pumps are commonly used for handling corrosive chemicals, while diaphragm pumps are ideal for handling abrasive fluids.

Maintenance of industrial chemical pumps is also crucial to ensure their longevity and efficiency. Regular inspection and maintenance of pumps can prevent costly breakdowns and ensure that the pumps are functioning at their optimal level. It is important to check for leaks, worn-out parts, and any signs of damage regularly. Additionally, proper lubrication and alignment of the pump components are essential for the smooth operation of the pump.

In conclusion, industrial chemical pumps play a vital role in the safe and efficient transfer of chemicals within industrial settings. Choosing the right pump for your specific application is essential for the success of your operations. By considering factors such as the type of chemical being handled, flow rate, pressure, and temperature requirements, you can select the best pump for your needs. Regular maintenance and inspection of pumps are also important to ensure their longevity and efficiency. Overall, industrial chemical pumps are a critical component of industrial processes, and proper selection and maintenance are key to their successful operation.

- Proper Installation and Operation of Industrial Chemical Pumps

Industrial chemical pumps play a crucial role in a wide range of industries, from chemical processing plants to pharmaceutical facilities. Proper installation and operation of these pumps are essential to ensure they perform efficiently and effectively. In this article, we will delve into the key aspects of industrial chemical pumps, including their applications and maintenance tips.

Industrial chemical pumps are specially designed to handle corrosive and abrasive fluids, making them ideal for pumping chemicals, solvents, and other liquids in industrial settings. These pumps are typically made from materials such as stainless steel, polypropylene, or other corrosion-resistant materials to withstand the harsh conditions of chemical processing.

When it comes to installing industrial chemical pumps, there are several important factors to consider. Firstly, it is essential to ensure that the pump is placed on a stable foundation and securely fastened to prevent vibrations and potential damage. Additionally, the pump should be installed in a well-ventilated area to prevent the buildup of fumes and gases.

Proper alignment of the pump with the motor is crucial for optimal performance. Misalignment can lead to increased wear and tear on components, reducing the pump’s lifespan. It is recommended to use precision alignment tools to ensure the pump and motor are perfectly aligned.

Another critical aspect of industrial chemical pump installation is ensuring the proper sizing of piping and fittings. Incorrectly sized piping can lead to inefficiencies and decreased pump performance. It is essential to consult with a professional engineer to determine the right size and configuration of piping for the specific application.

Once the pump is properly installed, it is crucial to follow maintenance best practices to ensure its longevity and performance. Regular inspections and testing of the pump components, such as seals, bearings, and impellers, are essential to identify potential issues before they escalate.

Proper lubrication of the pump bearings is also vital to prevent premature wear and ensure smooth operation. Using the correct type and amount of lubricant will help extend the life of the bearings and reduce the risk of breakdowns.

Regularly monitoring the pump’s performance and operating conditions is key to identifying any abnormalities or inefficiencies. Checking for leaks, unusual noises, or overheating can help prevent potential issues and ensure the pump is operating at its optimal level.

In conclusion, industrial chemical pumps are essential components in various industries, and proper installation and operation are paramount to their performance and longevity. By following the tips outlined in this article, maintenance professionals can ensure that their industrial chemical pumps operate efficiently and effectively, ultimately contributing to the success of their operations.

- Troubleshooting Common Issues with Industrial Chemical Pumps

Industrial chemical pumps play a crucial role in various industries, including manufacturing, pharmaceuticals, petrochemicals, and more. These pumps are specifically designed to handle corrosive, abrasive, and hazardous chemicals, making them essential for the safe and efficient transfer of liquids in industrial processes.

In this comprehensive guide to industrial chemical pumps, we will cover everything you need to know about their applications and maintenance tips. From understanding the different types of industrial chemical pumps to troubleshooting common issues, this guide will help you ensure the longevity and optimal performance of these critical pieces of equipment.

Applications of Industrial Chemical Pumps

Industrial chemical pumps are used in a wide range of applications, including transferring chemicals from storage tanks to processing equipment, circulating chemicals in cooling systems, and dosing chemicals in water treatment processes. These pumps are also utilized in handling abrasive slurries in mining and mineral processing operations, as well as in transporting hazardous chemicals in the petrochemical industry.

There are several types of industrial chemical pumps available in the market, including centrifugal pumps, diaphragm pumps, and peristaltic pumps, each with unique features and capabilities suited for specific applications. Centrifugal pumps, for example, are ideal for high-flow, low-pressure applications, while diaphragm pumps are better suited for handling viscous or abrasive fluids.

Maintenance Tips for Industrial Chemical Pumps

Proper maintenance is crucial for ensuring the longevity and efficient operation of industrial chemical pumps. Regular inspection and maintenance of these pumps can help prevent costly breakdowns and downtime in industrial processes. Here are some maintenance tips for industrial chemical pumps:

1. Regularly inspect and clean the pump components to prevent corrosion and build-up of debris.

2. Check for leaks or unusual noises during operation, as these could indicate potential issues with the pump.

3. Monitor the pump's performance and efficiency to identify any signs of wear or malfunction.

4. Follow the manufacturer's guidelines for lubrication and replacement of worn-out parts.

5. Ensure proper alignment and installation of the pump to prevent excessive vibration and premature failure.

Troubleshooting Common Issues with Industrial Chemical Pumps

Despite regular maintenance, industrial chemical pumps may encounter common issues that require troubleshooting. Some common problems include pump cavitation, low flow rate, and leaking seals. Here are some troubleshooting tips for these issues:

1. Pump Cavitation: Cavitation occurs when air bubbles form in the pump, leading to reduced efficiency and increased wear on the impeller. To prevent cavitation, check the suction line for leaks and ensure proper priming of the pump.

2. Low Flow Rate: Low flow rate can be caused by clogged filters, worn-out impellers, or insufficient pump speed. Check the pump components for any blockages or wear, and adjust the pump speed accordingly to increase the flow rate.

3. Leaking Seals: Leaking seals can lead to contamination of the chemicals being pumped and pose a safety hazard. Inspect the seals for wear and tear, and replace them if necessary to prevent leaks.

In conclusion, industrial chemical pumps are essential for the safe and efficient handling of corrosive and hazardous chemicals in various industries. By understanding their applications and following proper maintenance and troubleshooting tips, you can ensure the optimal performance and longevity of these critical pieces of equipment in industrial processes.

Conclusion

In conclusion, industrial chemical pumps play a crucial role in various industries by efficiently transferring liquids and chemicals. By understanding the applications and maintenance tips outlined in this essential guide, it is possible to maximize the performance and lifespan of these critical pieces of equipment. Regular maintenance, proper installation, and ensuring compatibility with the chemicals being pumped are all key factors in ensuring the longevity and efficiency of industrial chemical pumps. By following these tips and guidelines, businesses can ensure smooth operations and minimize downtime, ultimately leading to increased productivity and profitability. Remember, investing in the right industrial chemical pump and maintaining it properly is essential for the success of any industrial operation.