Best Practices for Installing Industrial Chemical Pumps

In today’s industrial landscape, the role of industrial chemical pumps is critical. These pumps are essential for ensuring smooth and efficient operations, from manufacturing to petrochemical industries. However, the stakes are high if installation is incorrect. From increased maintenance costs and operational downtime to potential safety hazards, the risks are significant.

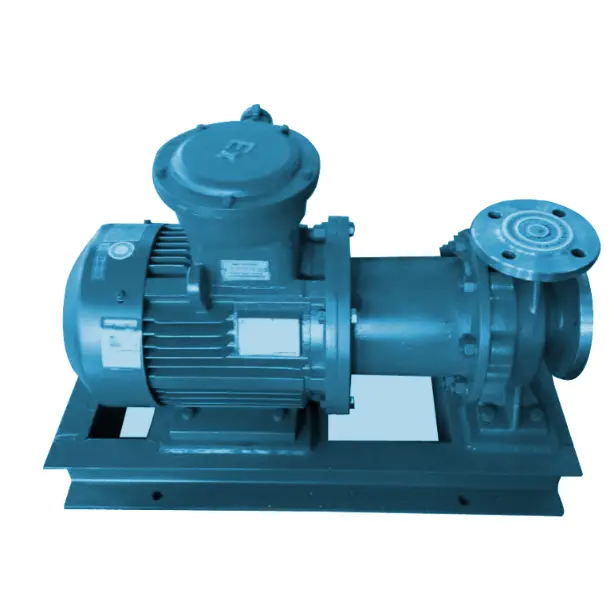

Industrial chemical pumps come in various types: centrifugal, reciprocating, and positive displacement. Each type has unique characteristics suited to different applications. Key specifications include flow rate, head (or pressure), and compatibility with specific chemicals. For instance, centrifugal pumps are ideal for handling large volumes at lower pressures, while reciprocating pumps are better for high-pressure applications. Choosing the right type and understanding specifications is crucial to match the pump's performance requirements with the industrial process.

Choosing the Right Location

The installation location significantly impacts pump performance. Proximity to the chemical source ensures efficient material flow, while elevation can affect pump performance, especially in centrifugal pumps, where higher elevation can lower head. Space constraints and environmental conditions, such as soil type and temperature fluctuations, must also be considered. A well-chosen location minimizes energy loss, reduces noise, and ensures longevity, all essential for a successful installation.

Proper Winneresting and Sealing

Winneresting is a critical step to prevent leaks and ensure pump longevity. Proper winneresting involves using materials that are compatible with the pumped chemical and techniques that ensure a watertight seal. Contaminant control is key to prevent the spread of harmful substances into the pumped medium. Seals, in particular, must be selected based on the pump type and application, ensuring they provide a reliable barrier against wear and tear.

Pre-Installation Preparation

Before installation, a thorough preparation phase is essential. The site must be cleaned and leveled to prevent settling of materials or equipment. Conducting pre-installation maintenance checks ensures no issues are left for the installation phase. Proper handling and storage of the pump, considering its weight and dimensions, are also crucial. This section emphasizes the importance of readiness for a smooth installation process.

Installation Steps and Procedures

The installation process begins with positioning the pump accurately, considering the application's requirements. Mounting involves securing the pump to the frame with appropriate clamps, ensuring it is aligned correctly for optimal performance. Securing the pump with couplings or flanges prevents unauthorized access and ensures safety. Attention to detail, such as checking for alignment and tightness, is vital for a successful installation.

Once the pump is correctly positioned, the next step is ensuring it is securely mounted. Properly tighten the clamps to prevent any movement that could compromise the alignment.

Post-Installation Testing and Calibration

After installation, thorough testing is necessary to ensure the pump operates as intended. Pressure and flow rate readings are essential to confirm the pump's functionality. Calibration involves adjusting settings to achieve the desired performance, ensuring the pump meets the required standards. This phase is crucial for identifying and resolving any issues before the pump begins operation.

Proper installation requires not only precise alignment but also the use of robust couplings to prevent unauthorized access. Ensuring these couplings are tight and secure is a critical step in the process.

Maintenance and Long-Term Care

Proper maintenance extends the pump’s lifespan and ensures continued efficiency. Regular cleaning, lubrication, and inspection are essential tasks. Identifying potential issues early allows for timely resolution, preventing costly repairs and minimizing downtime. A proactive maintenance schedule is recommended, tailored to the pump’s usage and environment.

Case Study: Successful Installation

A real-world case study provides practical insights into successful installation. A petrochemical company faced challenges due to uneven terrain and incompatible materials during the installation of a reciprocating pump. The company overcame these obstacles by carefully planning, using compatible materials, and ensuring thorough testing before operation.

Challenges such as uneven terrain or incompatible materials can lead to operational delays and costly repairs. A thorough planning phase, using compatible materials, and rigorous testing can prevent such issues.

Conclusion

In conclusion, the successful installation of industrial chemical pumps is not just about efficiency and safety—it’s about ensuring the longevity of your equipment and the reliability of your operations. By following these best practices, you can minimize downtime, reduce maintenance costs, and deliver a consistent, high-performance process. Remember, a well-planned installation sets the foundation for years of successful operation.

By adhering to these detailed steps and best practices, you can ensure your industrial chemical pumps operate efficiently and safely, supporting the smooth running of your operations.